Urethane Casting Service

Urethane casting (also known as vacuum casting) is an economical alternative to low-volume injection molding of plastic parts and can be used to closely simulate the final molded part or finished product. Urethane molding/casting is a process that combines 3D printing/CNC machining pattern with silicon molds to rapidly produce cast urethane parts that are similar in look, feel, and performance to injection-molded parts.

Mould life: About 20 years

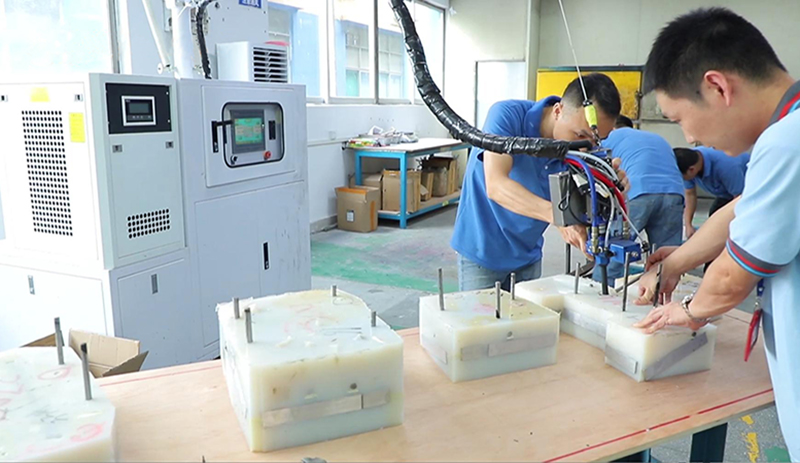

Vacuum casting machines: Imported vacuum casting system from Germany

Available Polyurethane material: ABS like, PP like, PA like, PC like, PMMA like, Rubber like, High-temperature resistant material, etc.

Description

Advantages of urethance casting service:

1. Urethane casting service can reproduce fine detailing; cast urethane parts can be painted and over-moulded.

2. Low cost: Urethane castines have a low mold cost and are suitable for low-volume production of 100 parts.

3. Short delivery time. Rapid turnaround time of parts, especially when using 3D printing to create master pattern, save development time.

4. Various casting resins that mimic the look, feel, and performance of injection moulded and engineering materials.

The urethane casting process involves three important steps:

The Master Pattern

The first step involves making a master pattern, which is made through 3D printing technology or CNC machining from the 3D file.

Molding

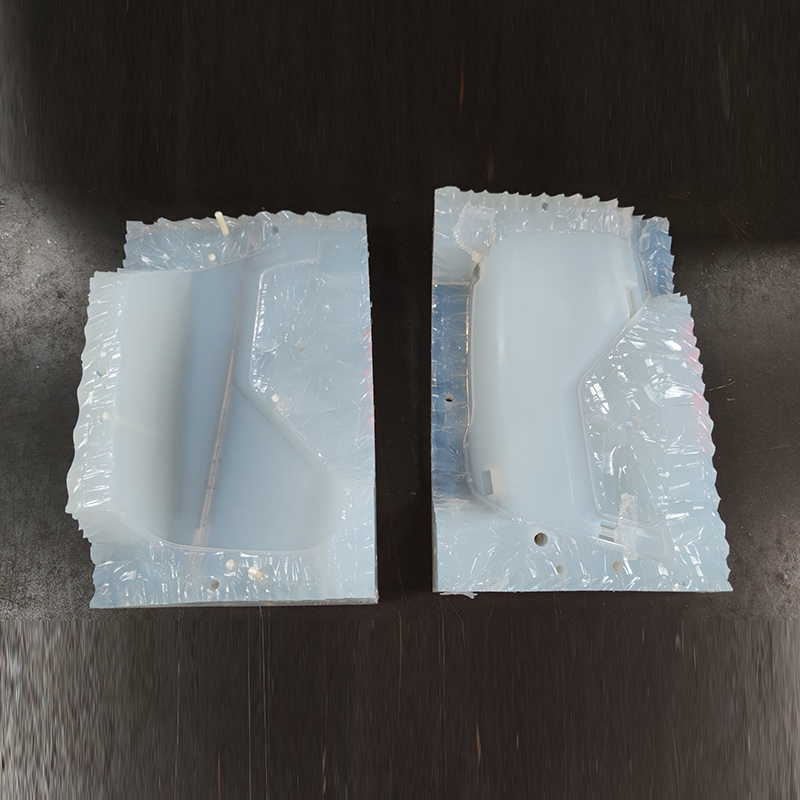

The second step involves pouring platinum silicone around master and using the master pattern to create a silicone mold.

Pouring

The third step involves pouring liquid polyurethane resin into mold, create polyurethane casting under vacuum.

Then the part is cleaned to remove excess burrs.