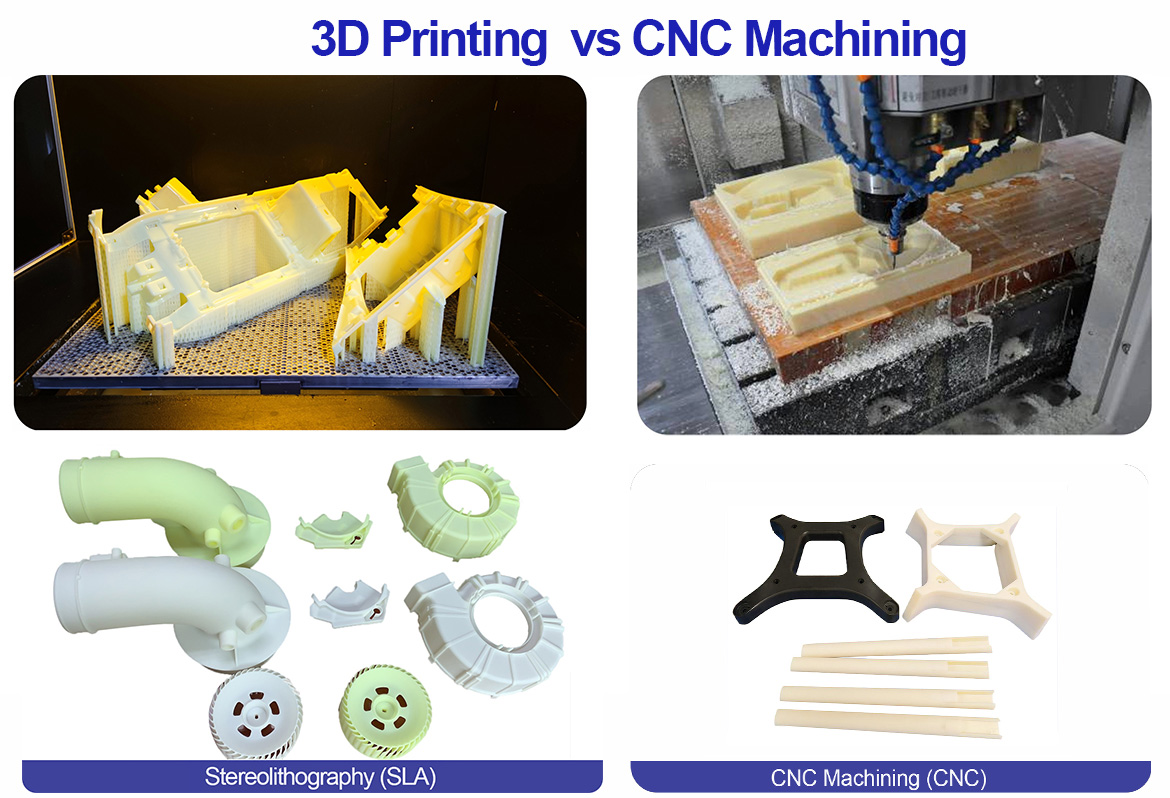

CNC machining and 3D printing have emerged as powerful technologies in the ever-changing environment of modern manufacturing. Computer Numerical Control (CNC) machining is a technique used in subtractive manufacturing processes that shape and carves raw materials into precise components using computer-controlled machines. Additive manufacturing, commonly known as 3D printing, builds three-dimensional objects layer by layer using different materials.

Comparative analysis of CNC vs. 3D printing is critical in modern manufacturing. So here we will share a thorough examination of CNC vs. 3D printing, comparing them across several critical factors to assist manufacturers in their decision-making process.

Comparative Analysis: CNC vs. 3D Printing

Here is a rundown of 6 main factors that will help you compare both manufacturing solutions.

1. Precision and Accuracy

While analyzing CNC vs. 3D printing, we saw that CNC machining has better precision and accuracy. With its high-speed rotary tools and multi-axis capabilities, CNC precision machining can achieve exceptional dimensional accuracy and tight tolerances. While 3D printing is constantly improving in this area, minor variations may occur due to layer adhesion and printer calibration.

2. Speed and Efficiency

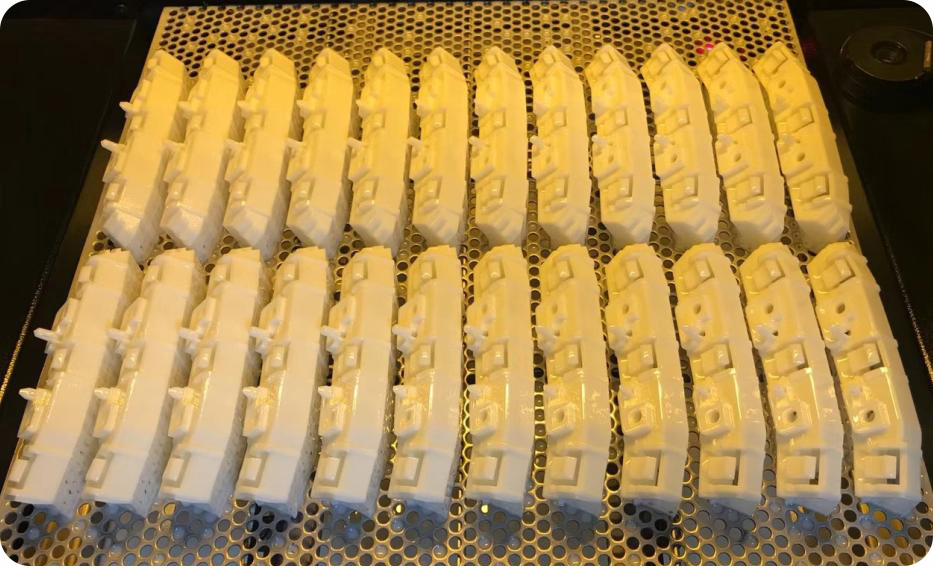

Regarding speed, 3D printing is advantageous, particularly when producing complex geometries. 3D printers can create intricate designs faster than CNC machines, which take longer to set up, change tools, and handle materials.

3. Material Selection and Compatibility

CNC machining can work with diverse materials, including metals, plastics, and composites. With its versatility, CNC machining is a popular choice for manufacturing parts that require specific material properties.

While analyzing CNC vs. 3D printing, it has been seen that though 3D printing’s material options have expanded over the years, it still has limitations regarding material strength, heat resistance, and chemical compatibility.

4. Design Complexity and Customization

When comparing design complexity and customization in CNC vs. 3D printing, 3D printing shines. Its layer-by-layer approach produces intricate and organic shapes that would be difficult to achieve with CNC machining. Furthermore, because 3D printing allows for simple customization and iteration, it is ideal for rapid prototyping and small-scale production.

5. Suitability for Prototyping and Production

CNC machining and 3D printing are beneficial in prototyping and production. However, CNC machining produces functional prototypes, and high-volume production runs with superior accuracy and surface finish.

On the other hand, 3D printing solutions are ideal for rapid prototyping, low-volume production, and on-demand manufacturing, especially when design iterations are frequent.

6. Cost-Effectiveness

CNC machining may require a larger initial investment due to expensive machinery and tooling costs, but it can provide cost advantages for high production volumes. 3D printing is relatively inexpensive for small-scale production but can be more costly for mass production due to material costs and longer production times.

Future Outlook and Emerging Trends

The future of CNC machining appears bright, with potential developments on the horizon. One trend is the increasing use of automation and robotics in CNC machining. This will allow for greater precision and productivity and the ability to create parts more quickly and efficiently. Another trend is the use of advanced materials and coatings in CNC machining. These materials can enhance the performance and durability of machined parts and enable the creation of more complex geometries.

Meanwhile, 3D printing is evolving with a slew of new trends with materials advancements, such as high-performance polymers and metal powders. Furthermore, the advancement of multi-material and multi-color printing techniques opens the door to new applications and expanded customization options.

Moreover, by combining subtractive and additive capabilities, hybrid CNC machines can provide the best of both worlds. This combination of CNC precision machining and 3D printing has the capacity to transform manufacturing processes by allowing the creation of highly complex and functional parts in a single setup.

Experience Seamless Manufacturing Excellence With SEAL-RP!

When it comes to finding the optimal CNC vs. 3D printing solutions, you can trust SEAL-RP. As an industry leader, we provide various cutting-edge manufacturing technologies tailored to meet the diverse needs of modern businesses.

Our unique selling points differentiate us from competitors. We have a cutting-edge facility outfitted with advanced CNC machines and high-quality 3D printers, ensuring precision and efficiency in every project. Furthermore, our experienced team of engineers and technicians is committed to delivering exceptional results while providing expert guidance and support throughout manufacturing.

The cutting-edge technology, experienced team, diverse material selection, and cost-effectiveness make us an ideal partner for all modern manufacturing needs. Trust SEAL-RP to bring your visions to life with unmatched quality and efficiency.