CNC machining, a subtractive manufacturing process, can be applied to different industries, such as the medical, automotive, and aerospace domains. Used almost daily, this machining mechanism has been supporting these industries since the 1940s. Manufacturers and machinists are benefiting from prototype CNC machining in various ways. The process is differentiated based on the required manufacturing process and materials as per the need of the production, and we are here to tell you all about it!

Common Materials Used For Prototype CNC Machining

When completing one-off and medium-volume production runs, the computer-controlled aspect of CNC machining is highly impacted by choice of materials. Each material has distinct qualities and complexities that affect the properties of the finished product and the overall production process. This makes the manufacturing process highly accurate, simple, and cost-effective.

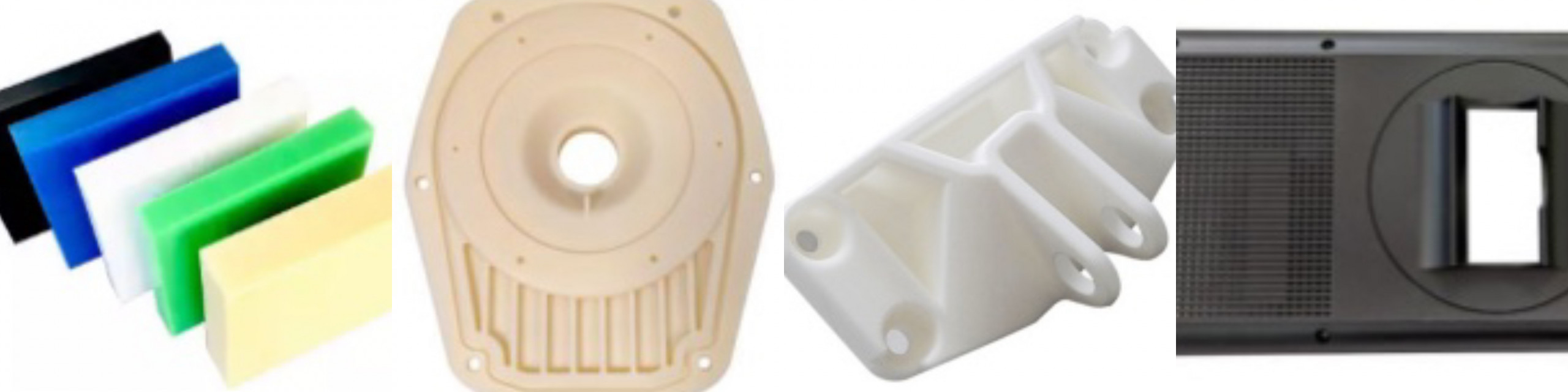

Common materials used for prototype CNC machining include the following:

1. ABS

ABS stands for Acrylonitrile Butadiene Styrene. It is a thermoplastic, amorphous polymer with mechanical qualities, including impact resistance. Rapid prototyping frequently uses this material, which has a wide range of uses but is especially well-suited for aesthetic designs and functional parts. This material is primarily used for processes like drilling, painting, gluing, polishing, sanding, filing, and so forth, and the finished products boast an excellent finish.

2. POM

Of all the CNC plastics, POM is one of the easiest to the machine. High-strength, high-stiffness plastic in this material offers excellent resistance to heat, wear, chemicals, and fuels. It also has good electrical properties, a low coefficient of friction, and little moisture absorption. Mechanical gears, linear guides, connector parts, and various customized parts are typical uses for CNC POM machined parts.

- PMMA

PMMA(polymethyl methacrylate)is a material that is inexpensive, simple to process, and versatile. It is frequently used as a lighter, more durable substitute for glass. This material for prototype CNC machining is the perfect choice for making parts that need to have excellent optical qualities, high UV stability, and good tensile strength.

4. PA (Nylon)

One of the most popular engineering plastics in the world, PA, also known as nylon, has excellent impact and wear resistance. In some situations, it may be utilized as a substitute for metal. Additionally, the composition is stronger and more stain-resistant due to its high crystallinity. Nylon also eliminates wear and corrosion problems and reduces the need for significant amounts of lubrication.

CNC Machining Processes

The machine’s primary function is to remove layers of material from the raw material in order to create unique shapes and designs. The fundamental steps in prototype CNC machining are creating the CAD model, transforming the CAD file to a CNC program, setting up the CNC machine, and carrying out the machining operation. Moreover, while the CNC machining process offers a wide range of features and operational processes, three basic processes are consistent across all of them.

- Turning

In the CNC manufacturing process turning, bars of material is rotated while being held in a chuck and fed to tools that remove material from the piece until the basic result is obtained. The machine has a fixed spindle and a cylindrical tool that rotates to remove material. It rotates quickly as a single-point cutting tool that chops away pieces of material.

- Milling

CNC milling employs computerized controls and multi-point rotary cutting tools to move and operate during the machining process. In contrast to turning, which uses a stationary cutting tool to spin the material, milling uses a computer to control a rotating cutting tool against a piece of material that is clamped down.

- Drilling

CNC drilling is a manufacturing process used to create holes in parts. It is a crucial process in manufacturing products and components. Depending on the component’s design, the holes are usually made to accept machine screws or bolts for assembly purposes and aesthetic processes depending on the design.

Advantages of Using CNC

With CNC, especially CNC machining plastic, cycle times are drastically cut, finishes are improved, and multiple processes can be finished at once. The assembly line can run smoothly and without any technical glitches thanks to the seamless fitting of parts made possible by the high-precision turning of components.

Additionally, prototype CNC machining efficiently uses the raw materials available because all precision CNC machines run repeatable software programs that use fixed instruments with a fixed route.

Looking for a reliable supplier for prototype CNC machining?

Turn to SEAL-RP’s extensive range of CNC machining to discover a reputable and trustworthy manufacturer of CNC machines. The CNC manufacturing equipment from us is made to offer premium CNC manufacturing service with various materials, including ABS, POM(Delrin), PMMA, PC, PP, and PA(Nylon). Our machines can be used to produce a variety of mechanical plastics with high levels of precision and speed, allowing the business to keep up with rising demand.

About SEAL-RP

SEAL-RP prioritizes innovation and consistently strives for excellent product quality while utilizing cutting-edge manufacturing techniques. We offer quick and efficient prototype CNC machining services for automotive, medical, home appliances, intelligent manufacturing, military, robotics, driverless, and other industries.