3D printing and urethane casting are among the most popular rapid prototyping solutions in design and manufacturing. Both of these technical solutions can be used to create almost any object, from a simple plastic toy to an intricately designed finished product, and that’s why they are highly praised for their flexibility and affordability.

But which is the best solution for your project? Is it better for your company to use urethane molded parts or 3D printing and design? Let’s go through this in detail.

What Is 3D Printing and Design?

3D printing and urethane molding are different industrial processes to create products. However, their uses are similar because they help make unique and creative items.

3D printing services, including SLA 3D printing (Stereolithography), SLS 3D printing (Selective Laser Sintering), and SLM rapid prototyping (Selective Laser melting). 3D printing and design is a process where a 3D model is created using computer-aided design (CAD) software. The object is then sliced into layers, each printed with a different material to create the object. This process can be repeated repeatedly to build up an object in layers.

It is a quick, easy, and cost-effective way to turn your ideas into products. These 3D printing prototypes help validate the design and identify and provide feedback on problems early in the product development process.

What Is Urethane Casting?

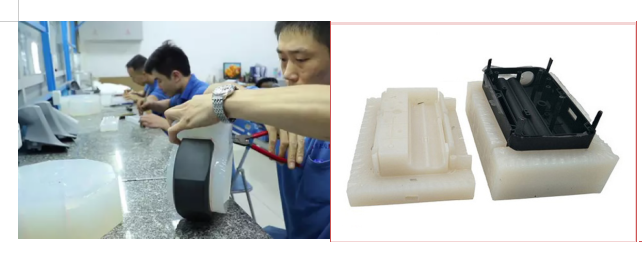

Urethane casting, referred to as polyurethane casting, is a process that involves the application of liquid urethane to a mold. Once the urethane has cured, the mold can be removed from the molding material and used in conjunction with a new pattern of liquid urethane. The original mold is then recycled into the next casting.

Using the urethane casting service is an excellent way to create molds for designers who want to produce multiple copies of their designs. It’s also useful for creating prototypes for testing purposes.

Comparison of 3D Printing and Urethane Casting

Now let’s compare different aspects of molded urethane parts and 3D printing and design for better understanding.

1. Material

3D printing and design covers a wide variety of materials, including transparent and translucent resins, PA, PA+GF, ABS resins, and metal materials. However, urethane casting is made from ABS, PP, PA, PC, PMMA, etc.

2. Surface fineness

Because of its ability to produce molds with flawless surface quality, 3D printing is significantly more precise than urethane mold making.

3. Application

3D printing and polyurethane molding are two popular manufacturing processes with a lot of overlap in terms of applications. In general, 3D printing is better suited for low quantities and intricate parts, while urethane casting is suitable for small-batch production. Both processes can create prototypes, low-volume production runs, and one-off parts.

4. Cost

3D printing and design is more cost-effective than urethane casting at low volumes. However, the latter costs less at more volumes (from 20-599). As a result, urethane casting is a better option when it comes to mass production.

3D Printing and Urethane Casting for Different Projects

3D printing and urethane casting are two solutions used in many different industries and applications. Each of these solutions has its advantages and should be selected based on projects. Sometimes, these two solutions are used together.

Get Professional Prototyping From SEAL-RP

To create a durable product, you will need a reliable supplier. So, where will you get your 3D printing and design and custom urethane molding?

Without any worry, you can connect with SEAL-RP. We are a one-stop shop for CNC plastic/metal machining, nylon casting, 3D printing, and cast urethane parts for rapid prototype machining. Our extensive client list demonstrates that we are a professional expert in the field. Get the best prototyping from SEAL-RP today!