Urethane or polyurethane casting has been gaining popularity in recent years. Due to its many advantages, it has a wide range of applications in the automotive, medical, robotics, aviation, electronics/appliances, and machinery industry. This article explains the top five advantages of utilizing urethane casting in manufacturing. It aims to provide insight into why this prototyping service is becoming increasingly popular among companies seeking to maintain their technological edge.

Urethane Molding Process

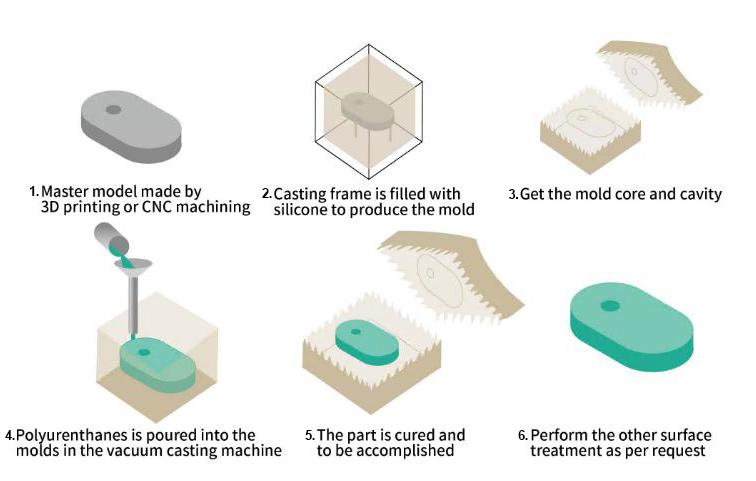

Let’s start with the cast urethane molding process:

- The polyurethane casting process is a three-step procedure, beginning with creating a master pattern. This pattern is constructed using 3D printing technology or CNC machining from a 3D file.

- The second step involves molding, where a silicone mold is created by pouring platinum silicone around the master pattern.

- This mold generates cast urethane molding in the third step. Liquid polyurethane resin is poured into the mold to create the desired shape under vacuum. Once the casting has been completed, it is cleaned to eliminate any excess burrs, resulting in a finished product ready for use. This highly versatile and cost-effective process makes it an excellent choice for small-scale production runs.

Top 5 Benefits of Using Urethane Casting to Revolutionize the Manufacturing Process

Numerous advantages of polyurethane casting can completely transform the manufacturing industry. Here are some of these benefits:

1. Cost Savings

Additive processes in prototyping can increase production costs by requiring multiple build cycles for more parts, while urethane molding allows for rapid prototyping without additional costly cycles, allowing for reasonably priced testing and product improvement.

2. Various Material Options

This technique can customize a wide range of material options, including ABS, PP, PA, PC, PMMA, rubber, high-temperature-resistant material, etc., for particular applications.

- Design flexibility

Components’ hardness, elasticity, and chemical resistance can be adjusted using different urethane formulations. Designers can produce parts with complex geometries and surface details thanks to the flexibility of cast urethane parts, enabling a more flexible and quick production process.

4. Short Lead Time

Creating silicone molds is quicker than making hard tools, with some molds becoming usable within a day of being poured. Most cast urethane parts can be shipped within two to four weeks using this method.

5. Excellent Performance

Castings made of urethane work exceptionally well in abrasion resistance, tear strength, and impact resistance. Because of these properties, urethane is perfect for demanding uses where parts must withstand challenging conditions, frequent use, or heavy loads. Due to its resilience and durability, the material is an excellent option for applications that call for vibration dampening, noise reduction, or shock absorption.

Please read the urethane casting service for more about its advantages and performance.

Gain A Competitive Edge With Custom Urethane Casting Services

Custom urethane molding is a flexible and dynamic service with many advantages for businesses. It is a desirable solution for applications that require flexibility, performance, and efficiency, as it can produce parts with specific physical and mechanical properties.

This custom service also enables businesses to optimize their production processes by providing affordable solutions for prototyping, small-run production, and specialized applications. They can gain a competitive edge and stay on top of trends by using custom urethane molding services.

To do so, businesses can follow these easy steps to request custom polyurethane molds:

- They should first specify their needs and requirements, including the kind of material, the quantity, and the lead time.

- Speak with a dependable and knowledgeable manufacturer or fabricator to discuss their needs and obtain a quote for casting services.

- Verifythe quotation and make corrections or additions if necessary.

- After the quote has been approved, the supplier can start the casting process and deliver the finished parts in the predetermined amount of time.

Revolutionize the Production Process with SEAL-RP’s Urethane Molding Services

It can be difficult to locate a reliable provider of urethane casting services. Collaborating with a provider with a solid track record, specialized knowledge, and a strong focus on maintaining high-quality standards is essential. SEAL-RP, a leading provider of rapid prototyping and casting services, stands out in this regard. We are known to provide quick turnaround times, competitive pricing, and a strong commitment to quality, which makes the company the best option for businesses needing custom urethane casting services.

With our expertise in various rapid prototyping services, such as urethane molding, 3d printing solutions, CNC manufacturing services, etc., we can help our clients reduce production costs and accelerate their time-to-market. If you are searching for a dependable partner to meet your prototyping requirements, visit SEAL-RP to explore our services and capabilities.